One of the most important stages in the process of implementing near-shore and off-shore wind power projects is the construction of a submarine cable connecting the wind turbine poles with the off-shore substation and the on-shore power grid.

In the context of Vietnam’s rapidly developing renewable energy industry, in which near-shore wind farms located along the coast play a key role in the transition to clean and sustainable energy.

Mr. Tung Lam Pham, Director of International Business in PC1 Group at “The Future Energy Show Vietnam & The Solar Show Vietnam 2023” held on July 12-13 in Ho Chi Minh City.

At these farms, the submarine cable line plays an important role in connecting the wind turbines with off-shore substations and the on-shore power grids. Speaking at “The Future Energy Show Vietnam & The Solar Show Vietnam 2023” held on July 12-13 in Ho Chi Minh City, Mr. Tung Lam Pham, Director of International Business, representative of PC1 Group said that: This is an area of special interest not only for the investor but also for the construction contractors.

95% of off-shore wind power plant projects have reported incidents related to submarine cables

Submarine cables are conduits of special material that endure extreme conditions on the ocean floor and ensure reliable transmission of electricity or data over great distances.

In a near-shore wind farm, these cables connect the off-shore turbines and the on-shore grid, which are critical to the overall operation and success of renewable energy infrastructures.

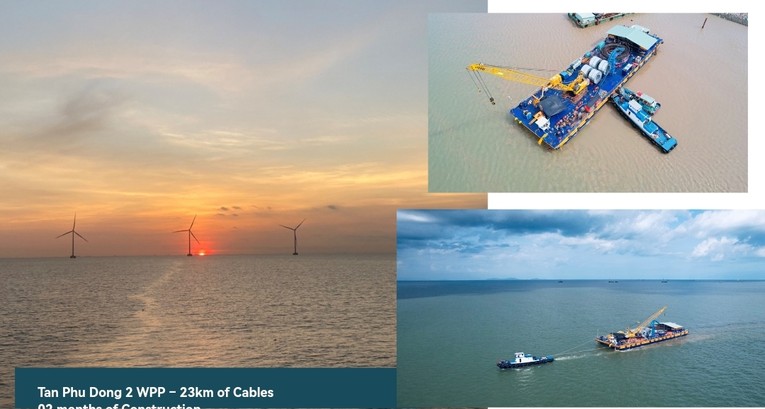

Tan Phu Dong 2 wind power project at Tien Giang Province

According to the PC1 representative, the process of installing and spreading cables is often lengthy and quite complicated in the marine environment. Secondly, it consumes huge resources in terms of machinery, equipment and human resources. These works also require extremely high accuracy and safety. Moreover, the cost of installation, repair and maintenance for the cables is also expensive. Therefore, the construction area needs to be deeply protected.

According to data published by Windpower Engineering & Development, 95% of off-shore wind power plant projects are often reported to have problems related to submarine cables. Of these, more than 40% of off-shore wind farm warranty claims involve cables. The cost of damage to submarine cables accounts for a very large proportion of 83% of the total damage cost of wind power projects. In addition, there are many other causes of incidents related to construction, electricity, collision, installation, wind turbines, lightning strikes, fires…

Whenever an incident occurs due to submarine cable, the farm will have to stop working to find out the reason and fix it. Solving problems related to undersea cables often takes a lot of time , seriously affecting the power output and revenue of the plant.

,…

In relation to information from the International Cable Protection Committee (ICPC) announced in March 2021, in the period from 1959 to 2021, the causes of sea cable incidents include: fishing (40.8%), unknown cause (17.8%), anchor (15.8%), 3rd party (9.5%), equipment damage (5.9%), geographic (4.7%), corrosion (4.6%), dredging (0.8%)…

Analyzing the causes of submarine cable problems at wind power projects in Vietnam, the representative of PC1 pointed out that the problem can originate from the design stage or during the construction process… For example, the design may be due to omission, wrong calculation, due to currents, topography of the construction area. As an effect, it is leading to erosion, exposing cables in the future, unsatisfactory the depth of cable protection, unsuitable anti-floating cable, or cement or reinforcing mesh…

The cause of failure from the construction process may be due to equipment not meeting technological requirements; The pit does not reach the required depth; Lack of construction monitoring system using sensor; Risks during construction; Lack of synchronization between devices; Risk of burial depth unsecured cable during shift or standing construction; The system lacks synchronization leading to risks for cables when buried…

What opportunities for local contractors?

Referring to the technology available in the market, Mr. Tung Lam said, the weakness of domestic construction technology is the rudimentary construction equipment system, the accuracy of the cable route ranges from 2-5m ( even up to 10m), the cost of compensation and site clearance of cable corridors, loss of cable length / cable redundancy factor…

There are other difficulties with European construction technology. The heavy equipment is difficult to access the shallow coast in Vietnam, and requires large resources to mobilize ashore (or use other construction methods such as excavators). Open-pit sand is often difficult due to soft sand, flowing and tidal disruption. Difficult to reach and ensure cable burial depth. Therefore, the time to destabilize the terrain of the excavation is longer and there is a potential risk of cable movement by digging.

As mentioned to contractors, according to the representative of PC1, foreign contractors often encounter problems such as the process of mobilizing machinery and equipment takes a long time, the preparation of the site and the large machinery also costs a lot of money and human resources are not available. Construction equipment after completion of work is re-exported or warehoused, not maintained in a state of readiness for warranty.

“Construction contractors need to be proactive in mobilizing construction resources, always available to carry out maintenance and troubleshooting. The foreign contractors often unsatisfactory these things”, said the representative of PC1. This is an opportunity for local contractors to improve their capacity to dominate this market through cooperation and learning more experience from oversea partners.

“Building international cooperation relationships is necessary for the development of domestic cable systems. In addition to sharing information and learning experiences, finding sources for procurement to synchronously upgrade equipment and technology, it is also an opportunity for cooperation to jointly invest or hire/purchase large ships from partners”, the representative of PC1 highlighted.

The practical solution of PC1

Tan Phu Dong 1 wind power project at Tien Giang Province

In order to meet the needs of laying submarine cables for off-shore wind power plants, from the end of 2020 until now, PC1 Group has researched, updat

ed and consulted advanced submarine cable construction technologies in the world, assessed the actual marine terrain conditions in Vietnam and offered the most suitable solution for each project. Accordingly, the construction time is shortened and less interrupted.

The synchronous machinery and equipment system researched, manufactured and operated by PC1 is always available. Reality has proven that the construction solution of PC1 is an underground digging robot with a minimum depth of 2.5 -3m, and after installation, the cable can be stable in the sand and soil. PC1’s submarine cable system is equipped with a synchronous positioning system, measuring and checking online; The oxygen supply system to support divers to help construction and cable inspection work clearly and conveniently, ensuring safety during cable pulling.

PC1 Group Joint Stock Company an expert in construction of coastal cable projects for near-shore wind power, typically the Tan Phu Dong 2 and Tan Phu Dong 1 wind power plant projects in Tien Giang Province.

At Tan Phu Dong 2 wind power project, with 23 km of near-shore submarine cable constructed in less than 2 months, PC1 Group performed much faster than the average construction speed in Vietnam.

The submarine cable line at Tan Phu Dong 1 Project with a length of 83 km (up to 20 km from shore) has been completed, tested and energized in 3 months. This is a record for the speed of construction of submarine cables across the sea in Vietnam.